Air Venting Method

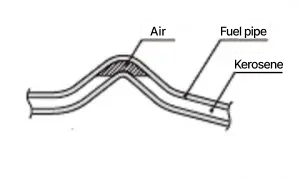

If the middle of the kerosene feed tube is twisted or in a tangled position, air will accumulate in the tube and kerosene will not flow, causing the “kerosene light” to blink and the heater will not operate. If this happens, please follow the procedure below. (Be careful not to spill kerosene.)

① Close the valve completely.

② Flatten the oil feed pipe so that there are no peaks (highs and lows) in the pipe.

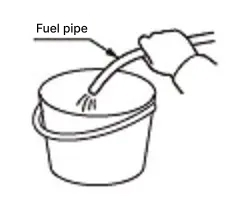

③ Remove the connection to the stove body, and insert a bucket or other container capable of storing kerosene at the end of the removed kerosene feed pipe and secure it so that it will not come off.

④ Fully open the valve, and confirm that kerosene flows out from the fuel feed pipe continuously without mixing air with the kerosene.

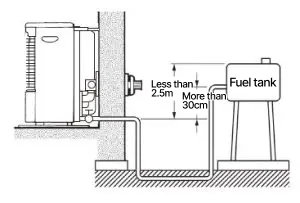

【Caution】If no kerosene flows out even when the valve is fully opened, there may not be enough space between the fuel tank and the stove body (approx. 30 cm is necessary), so please check and take appropriate measures.

⑤ After the confirmation, close the valve completely.

⑥ Connect the kerosene supply pipe to the stove body.

⑦ Fully open the valve.

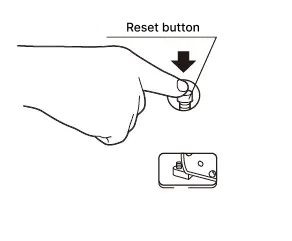

⑧ Press the red reset button on the side of the stove body downward once.

⑨ Operate heater.